Linz, Austria. Work is underway to build a major infrastructure project that will solve the traffic problems of the third largest city in the country.

The heart of the project involves the construction of a suspension bridge right outside the city center. A spectacular work, suspended between two mountain slopes: it is the fourth bridge over the Danube in Linz.

This is a great challenge, for a work created in a complex environment, with a restricted workspace and a very complex permit process.

This is the history of the A26 suspension bridge.

Austria

Austria

The A26 “Linzer Autobahn” motorway project is the important infrastructural work involving the Austrian city of Linz. The works started in November 2018: once completed, the A7 motorway and the B127 will be connected to each other, creating a new section of motorway that is essential for improving the viability of Upper Austria.

The city of Linz will instantly benefit from this project as it will alleviate the urban road network by re-directing up to 20,000 vehicles a day on the new A26. An optimized traffic distribution improving the quality of life of the population and of thousands of commuters in the region who will thus be able to travel shorter distances.

The new A26 develops in the western area of Linz and will have a length of 4.7 km. The construction works envisage two distinct areas and phases of intervention: during the first one, a complex system of tunnels was built - 85% of the total length (about 4 km) - and the bridge over the river, one of the key points of the whole project.

An important section of the A26 motorway involves crossing the Danube, and this is where the bridge is located: a 305 meters long structure with a weight of 2,200 tons. An evocative work that seems to float on the river, delicate and light, suspended without the aid of any pillars thanks to a system of stay cables anchored directly into the rock of the two banks.

How is it built a structure like this?

Linz. Danube bridge, part of the A26 "Linzer Autobahn" project, is highlighted

Linz. Danube bridge, part of the A26 "Linzer Autobahn" project, is highlighted

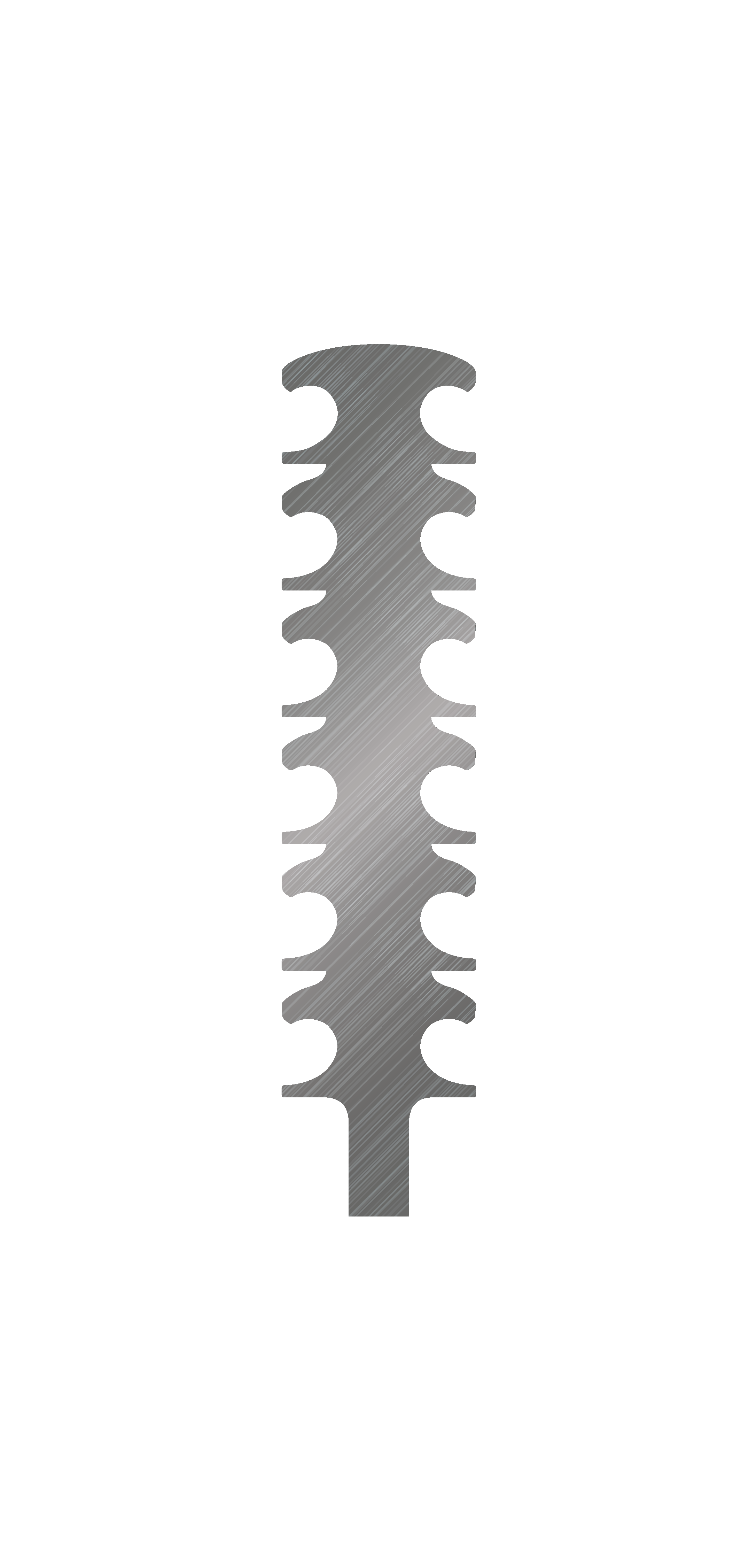

The first phase of the project included the installation, with minimum tolerances, of approximately 150 anchors with a depth of more than 100 meters into the ground, to anchor the concrete blocks to the ground through four 50-ton metal structures called "anchor swords".

The set of tie rods, anchor swords and concrete blocks is fundamental as it is the supporting point of the entire weight of the bridge trough which the loads are released. From this phase, the installation of the bridge could begin.

Cable draging via cable crane

The first step? The installation of suspension cables to connect the north bank to the south bank. To carry out this activity, a cable crane was installed through a drone that carried an 8mm synthetic rope over the Danube, dragging with it the steel cable of the cable crane.

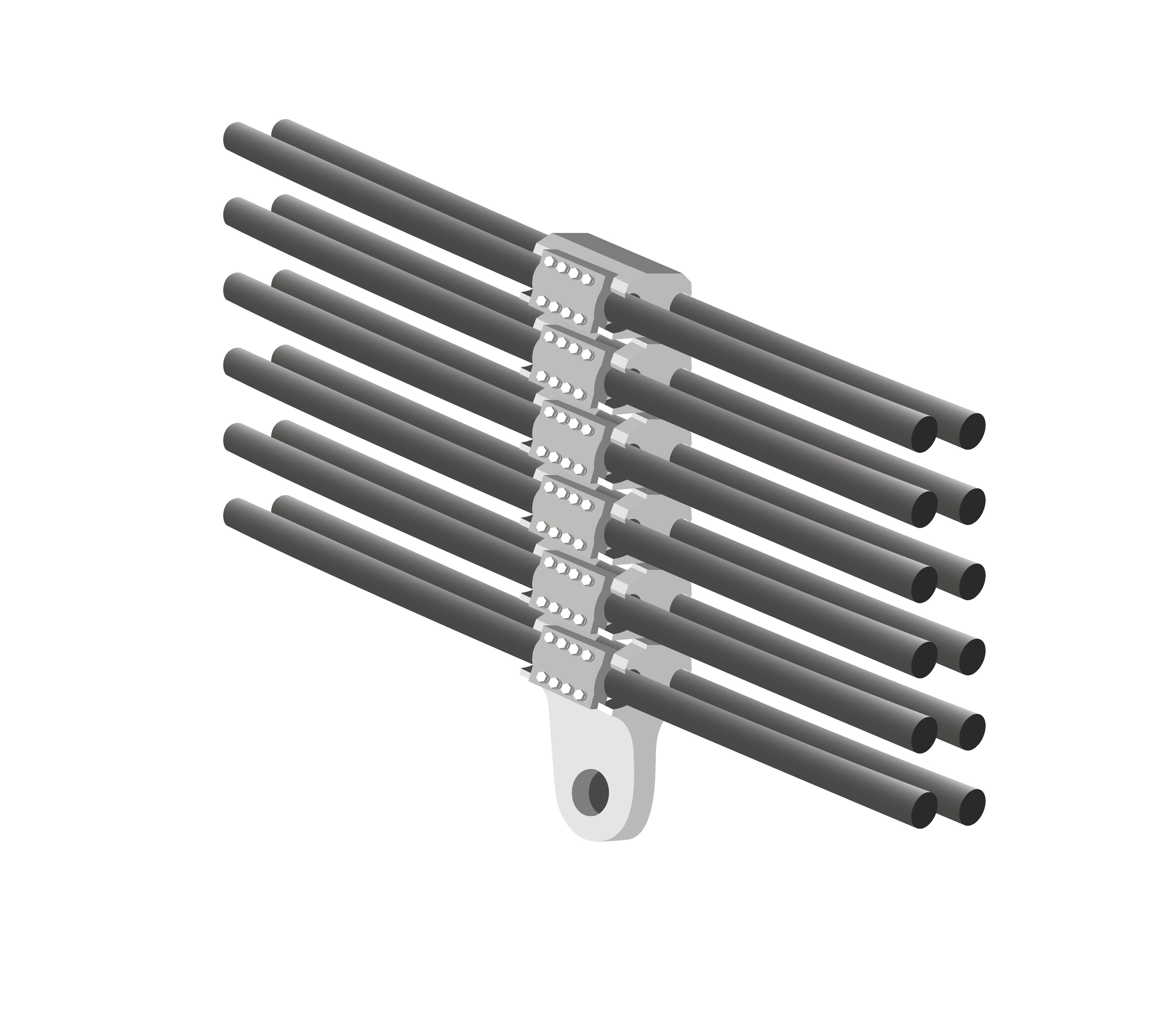

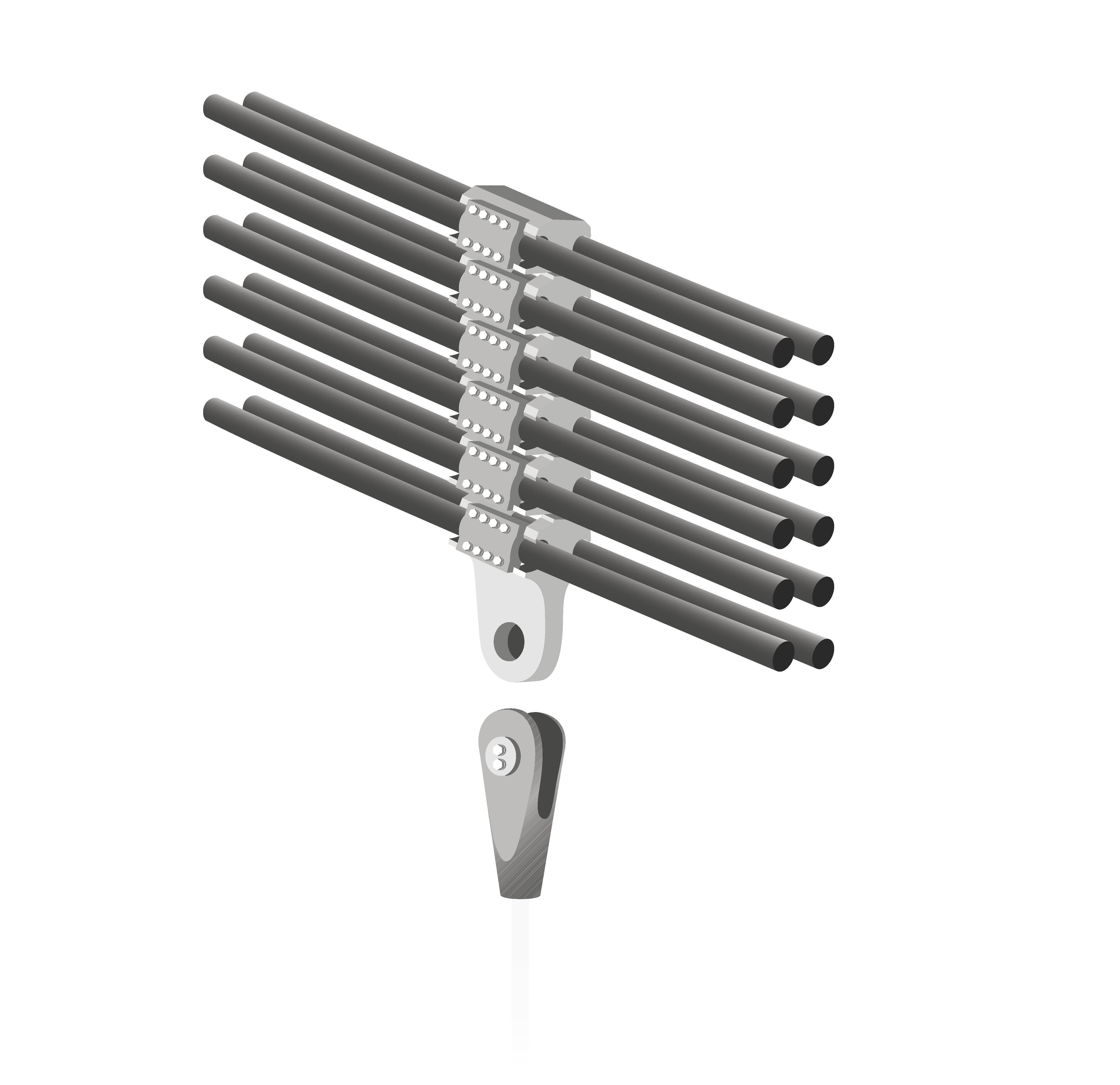

In the first 6 months of 2022, the cable crane began to unroll and drag the 24 suspension cables, 12 on each side, from the north bank to the south bank. Each cable was inserted into a specific machine that unrolled the cable from its reel and was dragged towards the other bank by the cable crane, accompanied by saddles that kept the cable in the correct position.

Once they reached the other bank, the end of each cable was inserted and hooked into the "anchor swords" that support its weight.

Clamps keep the cables in their final configuration

The bridge begins to take shape: it's time to install 60 connectors or clamps to keep the cables in their final configuration. These forged elements are tailor-made and were installed between August and September 2022, housing the 6 cables per side inside the cavities and stabilizing them using clamps fixed with bars.

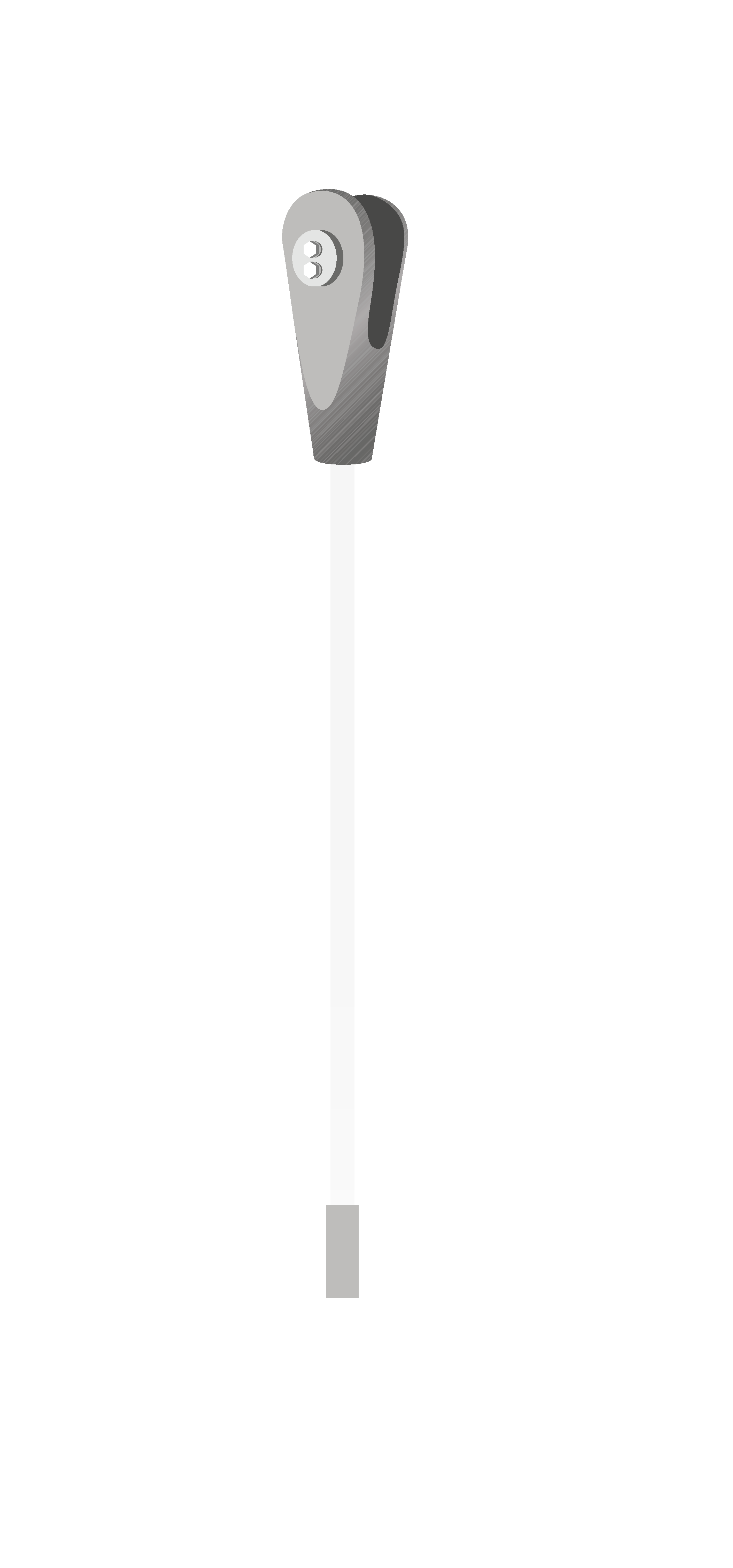

Installation of the hangers

One phase is missing before the installation of the deck: the installation of the hangers, whose function is to transmit the weight of the steel deck to the main cables. A delicate phase of the work, which took place in the month of October.

The hangers were harnessed and lowered from the cable crane to be hooked to the lower part of the connectors through a pin.

Widening and pushing outwards of the cables

Once the cables were installed, they lay parallel to each other. The final position of the cables, however, required the cables ‘position to enlarge towards the middle, therefore, they had to be widened and pushed outwards.

To carry out this activity, specially produced platforms were installed and, by using strand jacks at the ends, pulled the cables outwards and maintained their correct configuration until the temporary installation phases of the work were completed.

Laying of the deck by barge

We have reached the final part of the works: the laying of the deck over 300 meters long. The structure was assembled in a dedicated area along the river, 20 km away from the construction site and it was transported to the installation site by a barge, onto which they were loaded by means of self-propelled modular transporters or SPMTs.

Once the position on the river was reached, with the help of the cranes positioned on the barge and the strand jacks connected to the connectors at height, the bridge segments were lifted and placed in position.

Once the expected height was reached, the hangers were inserted in the dedicated spaces inside the transversal beams of the bridge. Once this operation was completed, the jacks were removed and all the load was definitively transferred to the hangers: the deck was finally in position, hanging from the main cables 20 meters above the Danube.

The last phase was the welding of the joints between the 8 macro-segments, allowing to continue with the subsequent installation activities of the bridge slab.

Il ponte completo